Safety checklists help to protect your company and employees for their safety and yours.

Bucket truck daily inspection checklist.

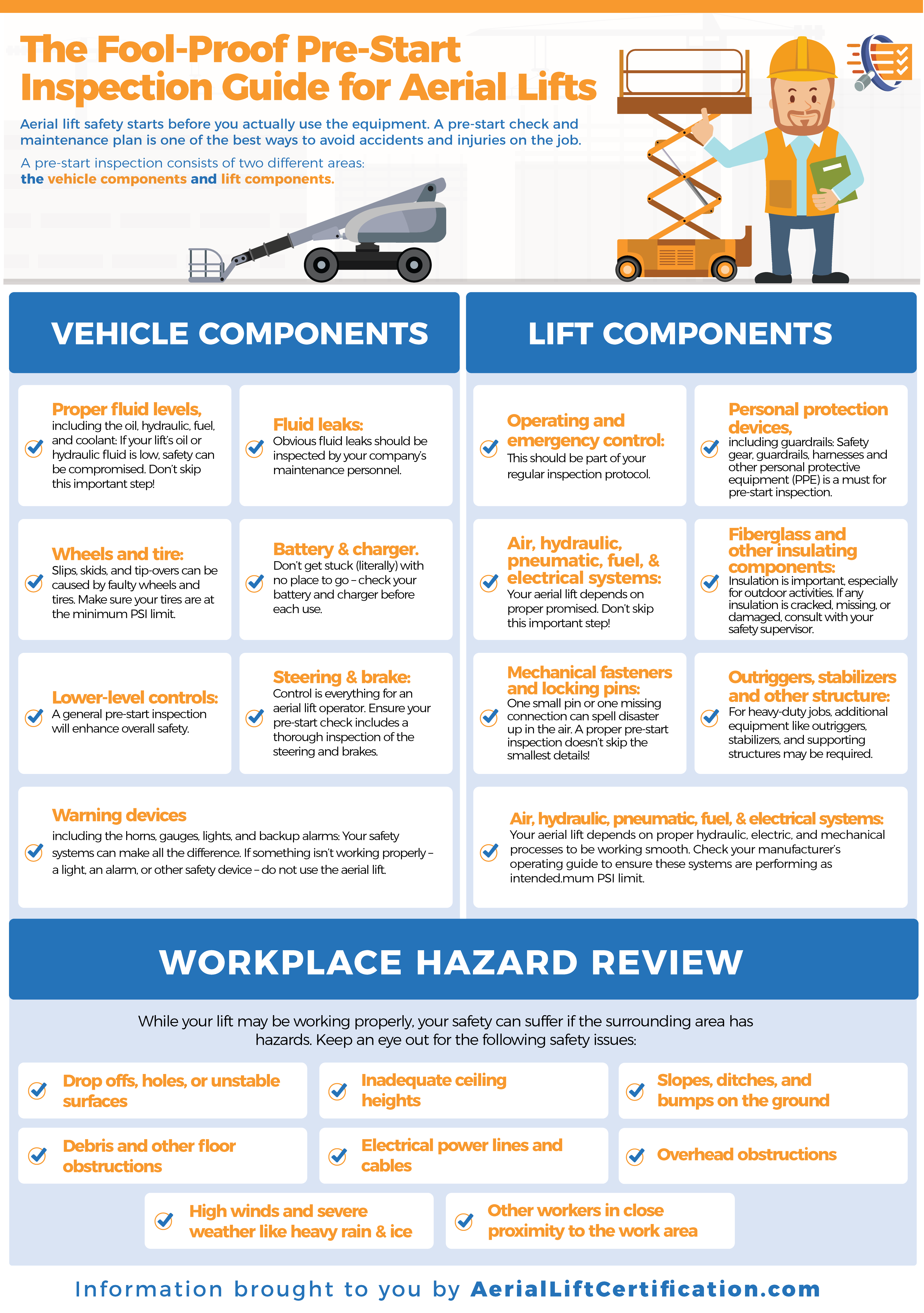

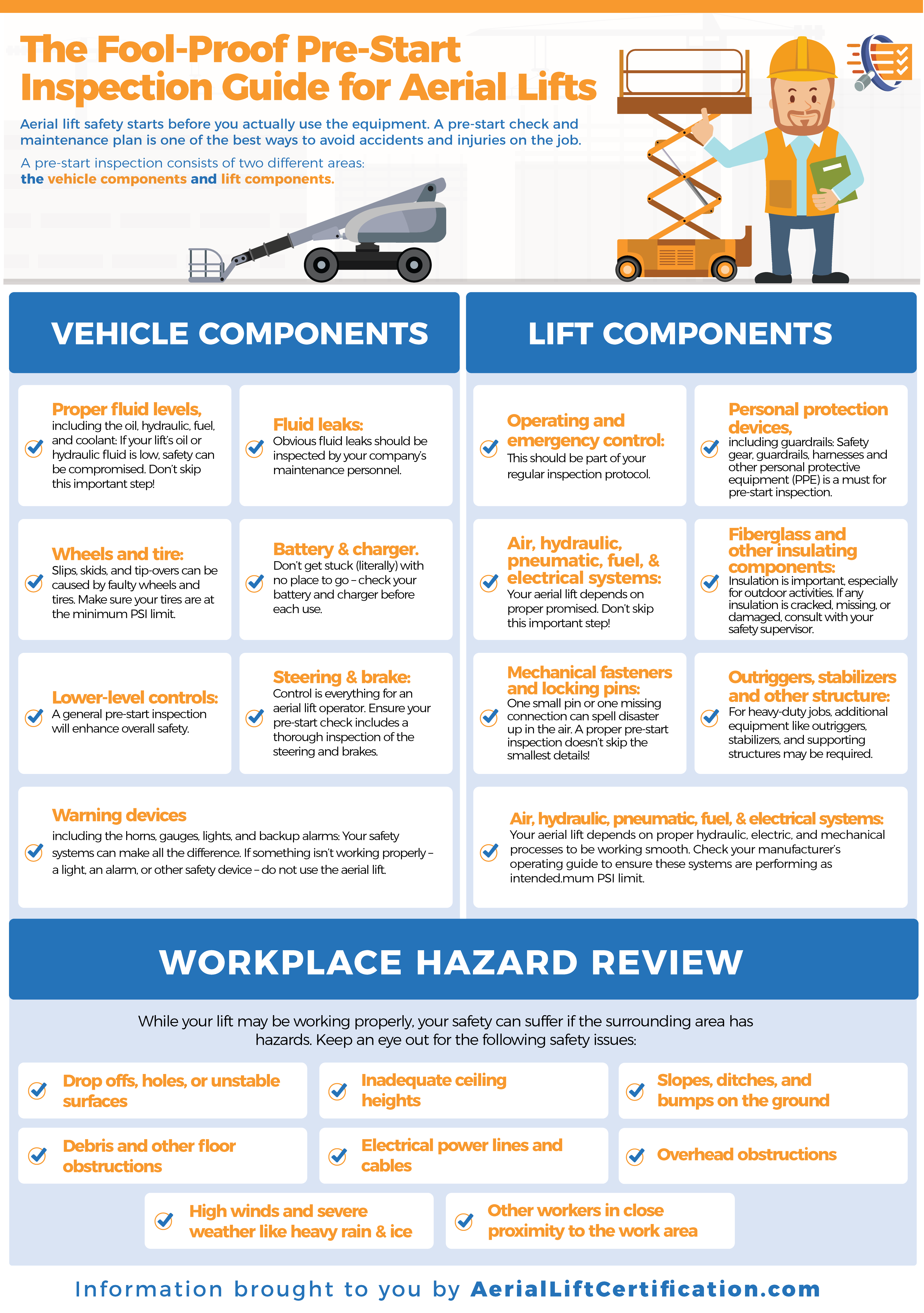

An aerial work platform inspection checklist can help you comply with osha safety standards and prevent accidents.

Bucket truck safety inspection form 1 of 1 10 13 11 oti system.

Set up maintenance and use continued.

Bucket truck inspection and maintenance initial inspection and test whenever new equipment is acquired owners are required to perform an initial inspection and test based on the manufacturer s manual.

Following a checklist look for dents cracks breaks leaks and damages in key areas that can possibly compromise the worthiness of the truck.

Identification reference prime contractor.

Inspection checklist for a mobile crane or boom truck revision 4 september 10 2009 doug y.

2010 itsc denver colorado.

Modifications modifications that might affect the safe operation of a bucket truck are not permitted without the written approval of the.

Using this truck inspection checklist on the iauditor mobile app begin by recording the type identification and mileage of the vehicle and take a photo of its general condition.

Before putting a bucket truck to work a thorough visual inspection should be performed each and every day.

Front end loader pre use inspection checklist operator.

This template then prompts the inspector to check the administrative conformance brake system fuel system trailer conditions and other components.

If you are concerned about putting together a bucket truck safety inspection checklist there is no need to stress.

Size 8 1 2 x 5 1 2.

Typical bucket truck vehicles.

Power off checks status ok no n a power on checks status ok no n a 1 underneath machine.

Altec s 12 month preventive maintenance inspection is a complete factory specified service performed by one of altec s certified maintenance technicians.

Daily visual inspection.

Most important this checklist helps you and your coworkers stay safe on the job.

Bucket truck aka aerial lift 2010 itsc denver colorado.

This inspection covers every point on the unit including filters lubrication and critical fastener torque procedures as well as a visual inspection for cracks and general wear and tear.

This safety checklist will take just a few minutes to complete and provides a way to systematically check all equipment for any discrepancies before each use.

11 unit starts and runs properly m m m.